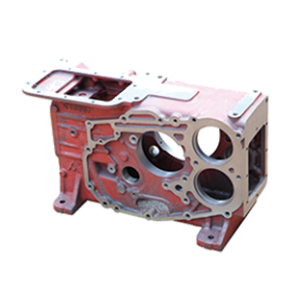

Casting Service

| Process | Material | Capability |

| Casting | Grey Iron: HT150, HT200, HT250, HT300 SG Iron: QT400-18, QT400-15, QT450-10, QT500-7, QT600-3, QT700-2

Steel: ZG200-400, ZG230-450, ZG270-500, ZG310-570, ZG340-640 |

20000T/Year |

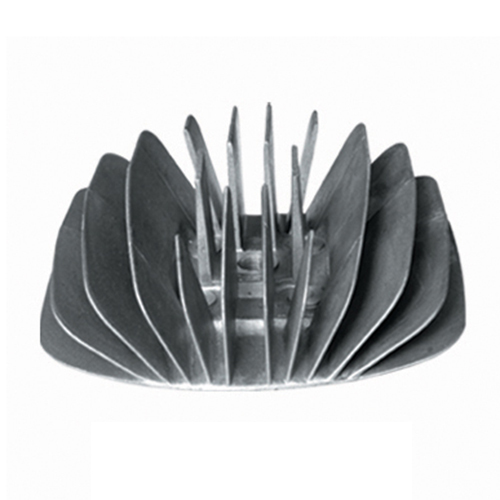

| Die Casting | Alloy suitable for High-pressure die cast, such as ADC12, A356, etc | Die-casting Machines(250T-800T) |

| Machining | Iron, Steel, Alloy, Stainless Steel | Brother & DMG Machining Centers Four-axis, Five-axis CNC, Honing Machines |

| Surface Treatment | Iron, Steel, Alloy, Stainless Steel | Painting, Electrophoresis, Electro-plating |

| Mould Workshop | Iron, Steel, Alloy, Stainless Steel | Developing mould on site |

Equipment

– Iron Casting Equipmenta

– Alloy Die-casting Equipment

| Full Servo Die-casting Machine | Quantity |

| 250T | 1 |

| 280T | 1 |

| 400T | 3 |

| 500T | 1 |

| 800T | 1 |

– Machining Equipment

– Mould Workshop

Machining Centers, Omiron Electrospark…

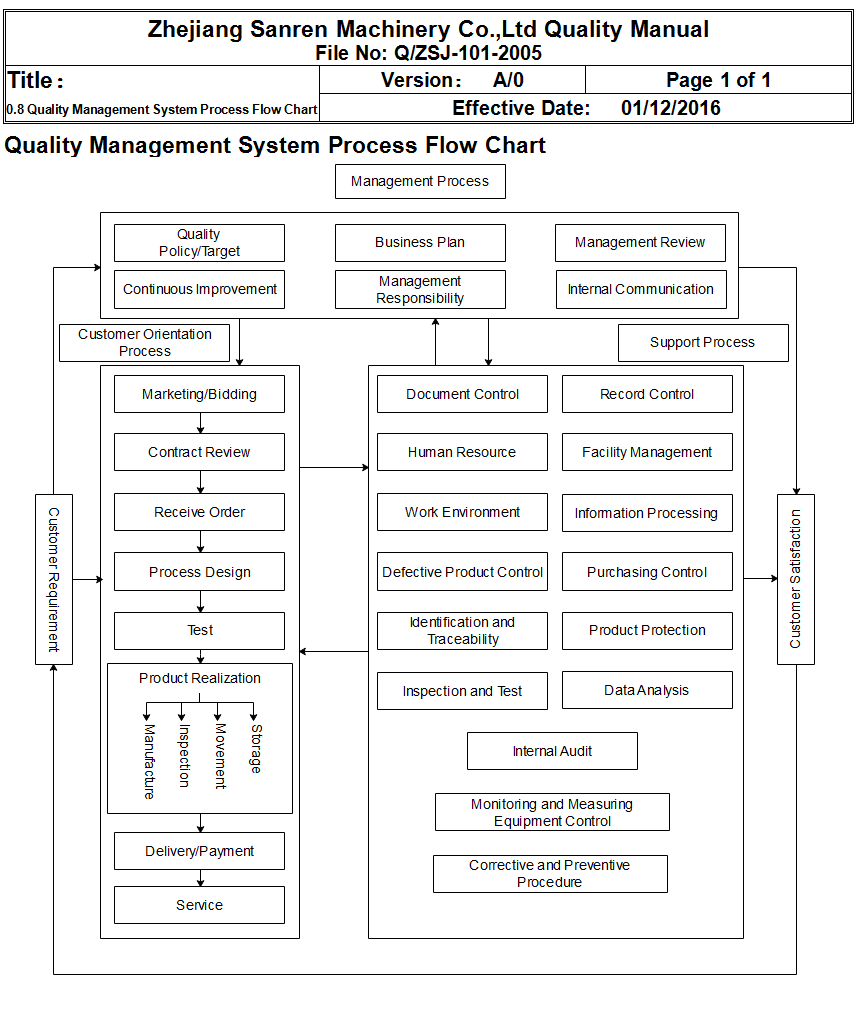

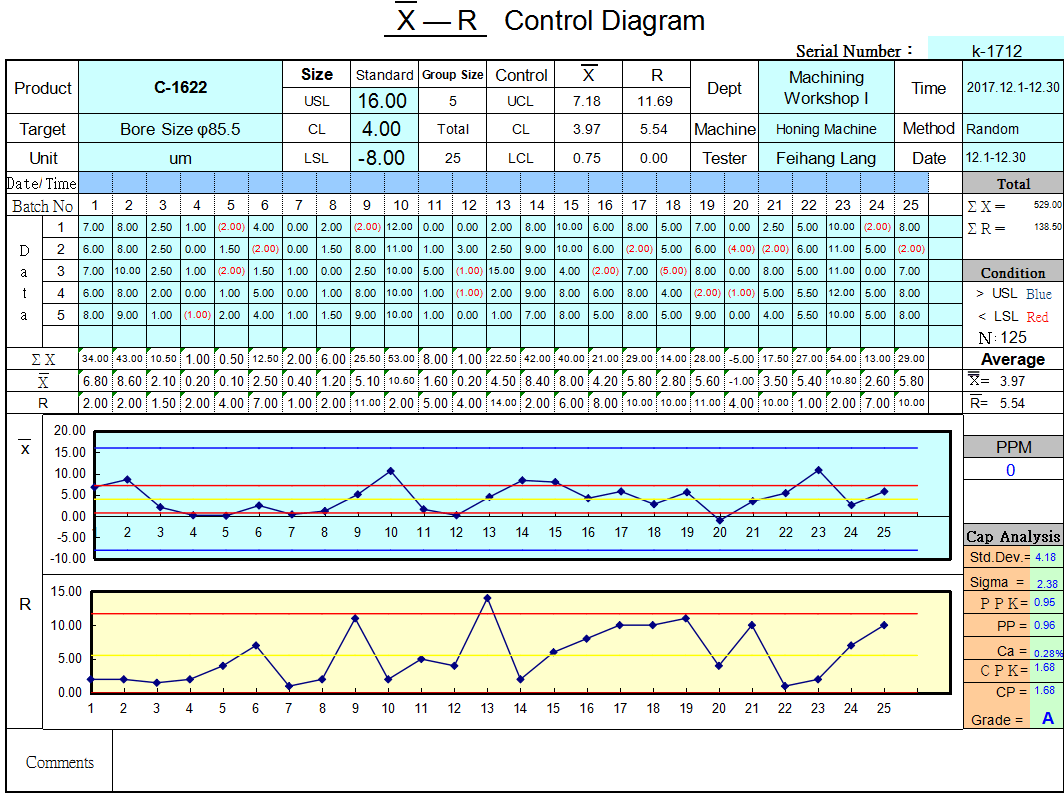

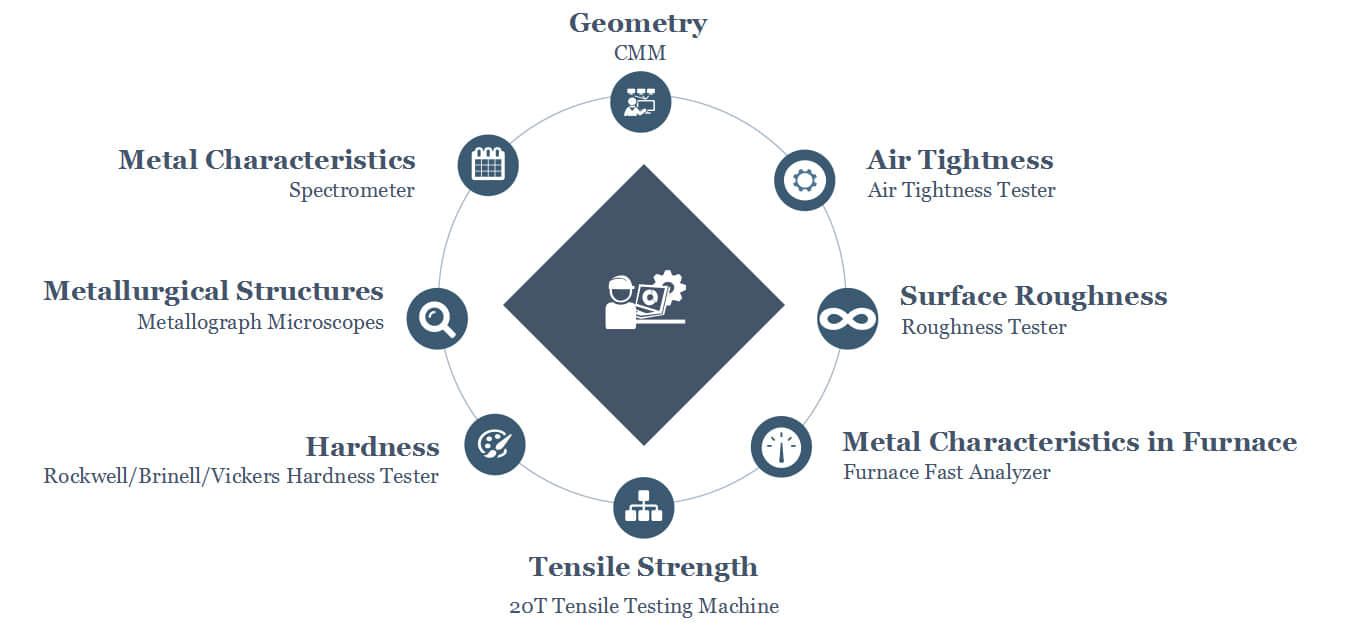

Fully Control of Quality

Efficient Development Process

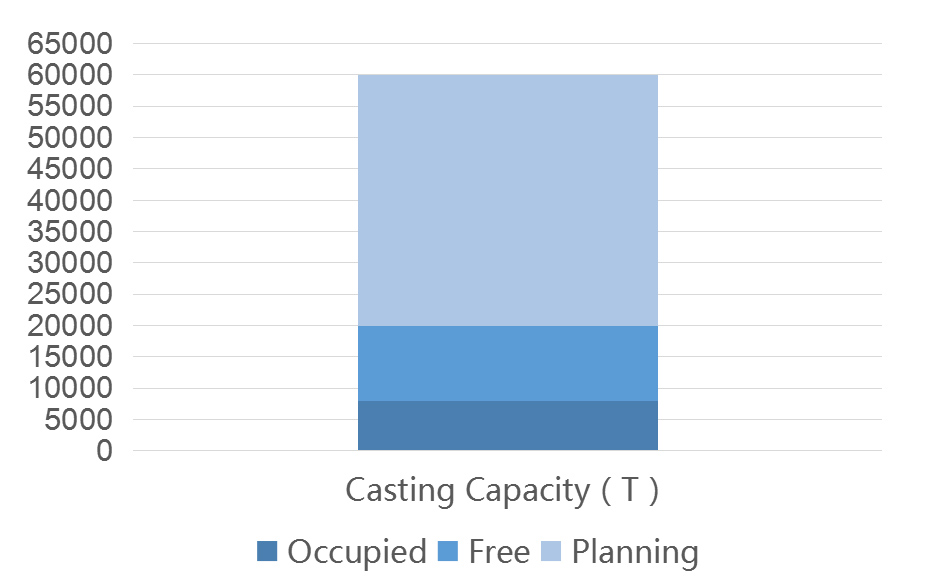

Iron Casting Capacity Status

Quality Assurance

– Machining Equipment

– Control Systerm

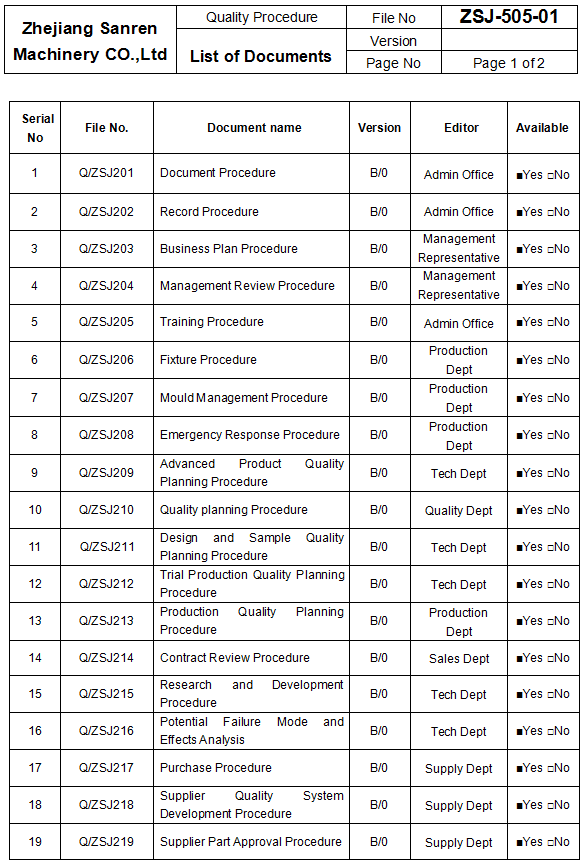

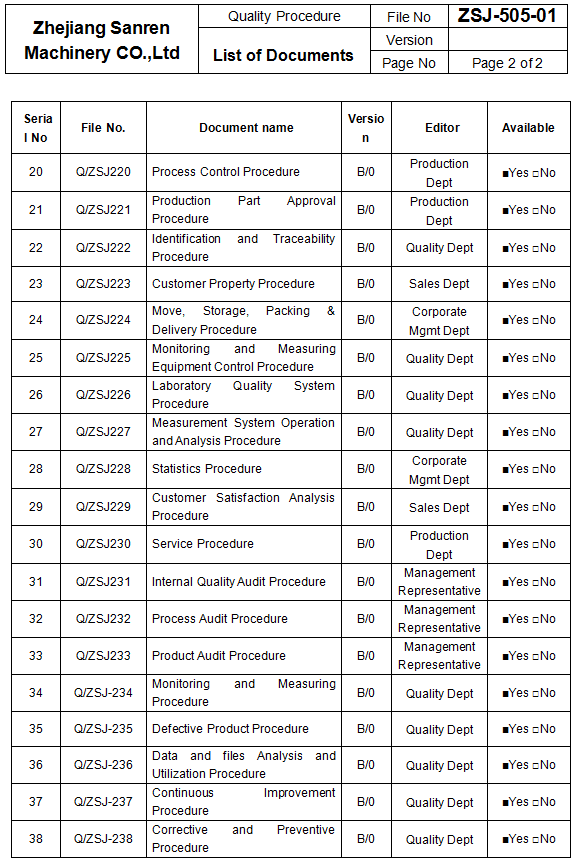

Technical Documents

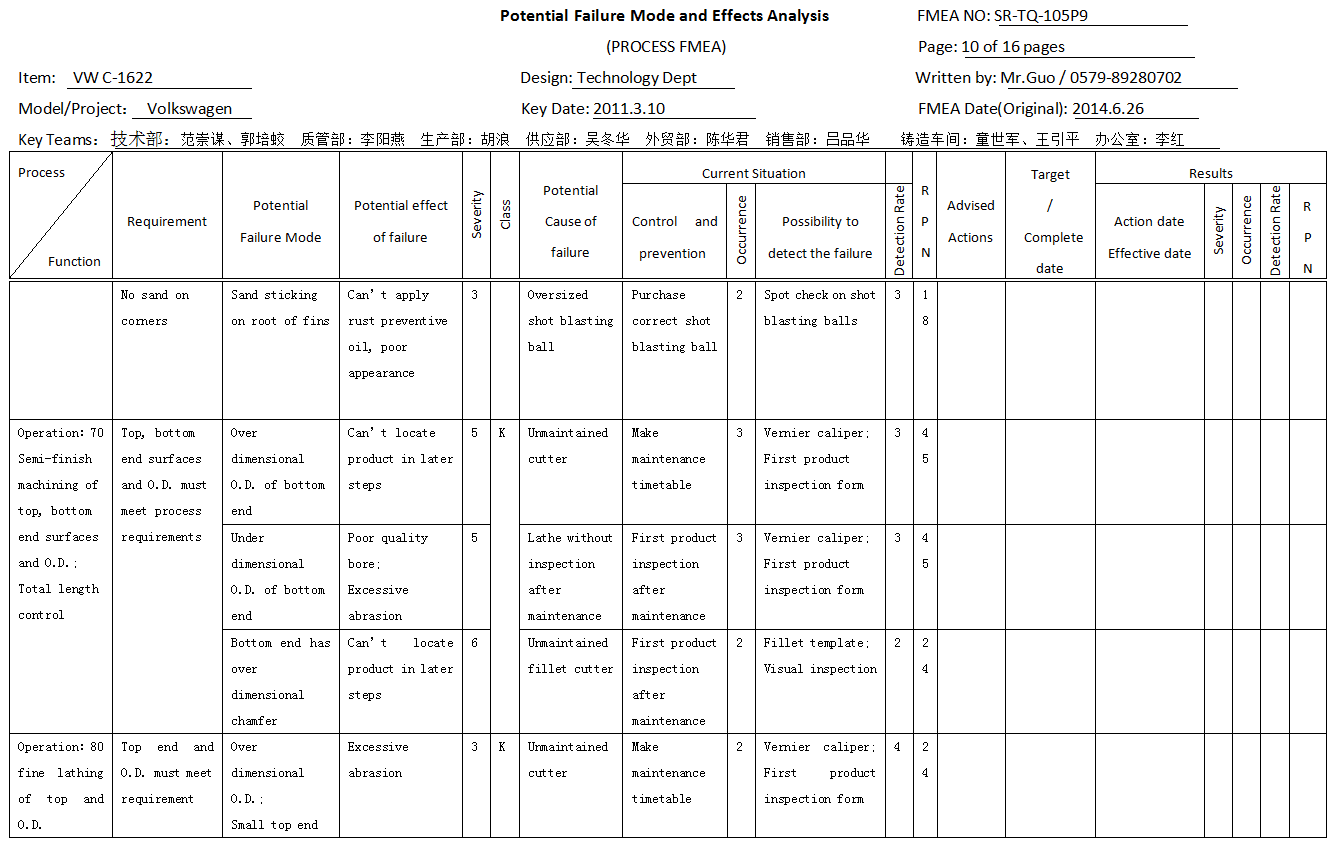

(FMEA)

(Measurement System Analysis)

(Quality Procedure)

(Quality Manual)